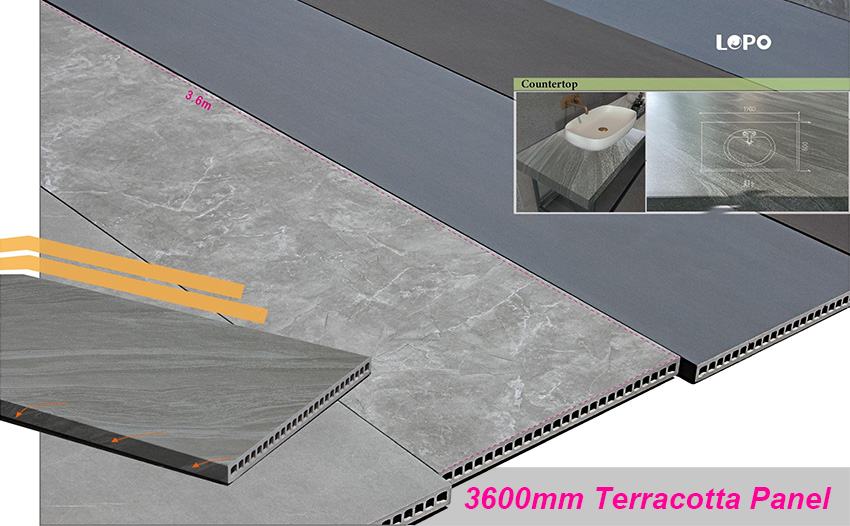

LOPO Terracotta Corp.’s 3600mm Panels: A Technical Breakthrough in Building Materials

In the dynamic field of architectural materials, LOPO Terracotta Corp. has emerged as a game-changer with the introduction of its 3600mm long dry-hang terracotta panels. This technical marvel is not just a triumph of size but an embodiment of advanced engineering and innovative material science. In this deep dive, we explore the intricate technical aspects that position these panels at the forefront of modern architecture.

Technical Innovation at Its Core

The 3600mm terracotta façade panels from LOPO Terracotta Corp. represent a significant leap in the realm of building materials, primarily due to their remarkable length. But what truly sets them apart is the complex engineering behind them. The panels boast an incredibly low water absorption rate of 0-3%, a feature that substantially increases their durability and suitability for a wide range of environmental conditions. This low absorption rate is crucial in preventing damage and deterioration over time, especially in areas prone to high humidity or rainfall.

Another standout feature is the high fracture strength of these panels. Being 30% stronger in terms of breakage resistance compared to other materials of similar thickness, they offer an unprecedented level of safety and longevity. This strength is a critical factor in their application in large-scale construction projects, where durability and reliability are non-negotiable.

Overcoming Production Challenges

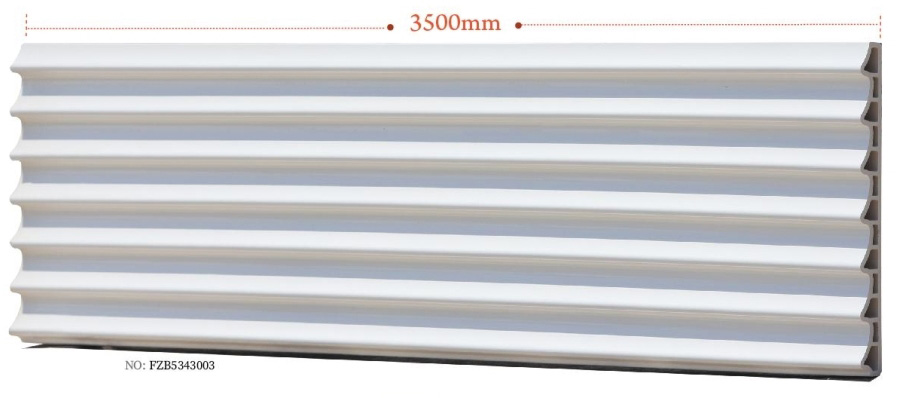

The production of these extra-long panels was not without its challenges. LOPO Terracotta Corp. had to rethink and innovate every step of their manufacturing process to accommodate the unique dimensions and properties of these panels. Customizing production equipment and technology was a significant hurdle. The company had to design and adapt its machinery, particularly in the molding, sintering, and cutting stages, to handle the extended length without compromising the structural integrity of the panels.

Precise control over the production parameters was another critical aspect. The company implemented advanced techniques to meticulously control temperatures and pressures during the manufacturing process. This precision was essential to ensure that each panel met the stringent quality standards set by LOPO Terracotta Corp.

Redefining Installation and Application

The challenges extended beyond production to the installation of these panels. Given their size, transporting and installing these panels posed logistical and technical challenges. LOPO Terracotta Corp. developed innovative solutions, including specialized packaging and transportation methods, to ensure the panels’ safety and integrity from factory to site.

The installation process also demanded new approaches. The company provided specialized training and tools to ensure that the installation of these large panels was not only efficient but also met all safety standards. This effort ensured that the architectural integrity and vision could be realized in every project.

Conclusion

LOPO Terracotta Corp.‘s 3600mm long dry-hang terracotta façade panels are more than just an architectural material; they are a testament to human ingenuity in material science and engineering. These panels have pushed the boundaries of what’s possible in building materials, offering architects and designers new horizons of creativity and innovation. As we continue to witness the impact of these panels in modern architecture, it’s clear that LOPO Terracotta Corp. has not only redefined the standards for terracotta panels but also laid down new pathways for the future of architectural design and construction.