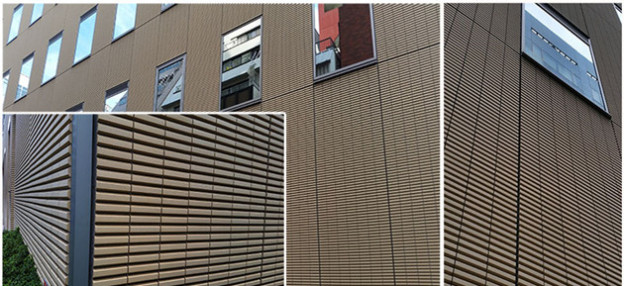

Faced Precast Concrete – LOPO Clay Thin Brick

A precast wall is a great solution for providing stability to the structure of a building’s frame, especially when used with the correct chemical for concrete. When also featuring controllable quality, short production and installation period, environmental friendliness, high safety level, and other merits, the use of a precast wall has been widely applied in more than 60% of the projects in developed countries including European countries, America and Japan. Understanding why concrete blocks and walls are used in the construction of commercial buildings is important, as it has many advantages. Construction that is done by keeping good practices in mind can help in ensuring the building’s safety and energy saving. In China, as construction industrialization has become a major trend in the development of the nation’s construction industry, the new 13th Five Year Plan has set a clear goal with regard to construction industrialization.

As for the precast clay wall cladding of the walls, apart from precase concrete veneer, many other cladding materials can be combined with precast walls. As early as the 1960s, American designers were active in innovation and applied many traditional cladding materials to precast walls. This can not only fully utilize the advantages of the precase concrete walls, but also create distinctive or traditional appearances for the walls, and can bring the special advantages of other cladding materials into full play.

Among traditional cladding materials, clay facing materials are the most commonly used ones. And among the clay facing materials (mainly including Clay Brick, ceramic tile, porcelain, and Architectural Terracotta, etc.), clay thin brick has unrivaled comprehensive advantages when used as precast cladding:

1. Rich in finish and color, including monotone or multi-tone color schemes; smooth or shaped surfaces; able to achieve rich visual effects and styles when matching with different colors or laying patterns;

2. Made of natural clay: safe, recyclable, and environmentally friendly;

3. Light in weight, causing no burden to the walls.

4. Simple in installation, and easy to be modularly embedded in the precast wall panels;

5. Excellent freeze/thaw performance;

6. Excellent weather resistance and corrosion resistance.

Not all clay thin bricks are suitable for precase concrete panels. The design and application should take the difference in properties between clay thin bricks and the concrete backers into consideration, like coefficients of thermal expansion, the shrinkage rates of concrete, and the connection design and hygroscopy of clay thin bricks, which may cause a potential bowing problem. You can learn more about this by contacting professionals like Milwaukee concrete services (or any other, depending on where you live), as they would clearly have a good idea about such technicalities. Moreover, most associations in western countries (for example, Precast/Prestressed Concrete Institute(PCI) in the U.S.) have clear requirements with regard to technical parameters of clay thin bricks like dimension, dimension tolerance, warpage, frost resistance, water absorption, coefficients of thermal expansion, etc.

Calcinated from high-quality clay extracted in China at high temperatures (about 1200℃), LOPO clay thin bricks boast comprehensive properties conforming to the requirements of western countries on cladding materials of precast concrete walls. LOPO clay thin bricks are not only recognized and used by the domestic construction industrialization pioneers like Vanke and Bhome, but also applied to precast concrete panel projects in many countries including European countries, South Korea, Japan, and Australia.